Home » Articles posted by Olivier Garrett

Author Archives: Olivier Garrett

What Does it Take to Become a Stone Mason?

Stone Mason Charleston SC must have good physical skills, including strength and dexterity. They also need to read and understand technical blueprints and instructions from builders and architects.

Masons work in both indoor and outdoor settings. They install stone components on construction sites, such as walls, arches and columns. They also carve intricate designs on stones to add beauty and artistic flair.

The work environment for a stone mason is often harsh and demanding. Masons must be able to tolerate a variety of weather conditions, including hot and humid summers and chilly winters. They may also work on sites with a lot of noise and traffic. They also need to wear appropriate clothing, as their job requires them to be outdoors in all kinds of weather. Masons must also take a health and safety course in order to work on construction sites.

Many people who work as stonemasons start out in other types of masonry jobs, such as bricklayers or block masons. They can then choose to specialise in stonemasonry or move into other areas of masonry, such as monumental masonry or building restoration. The majority of stone masons are self-employed. Some work for monument fabricators or are employed by private individuals to make memorials. Others are employed by construction companies to build stone structures or by local governments to repair and maintain public buildings.

Stonemasons can work either as a banker mason in a workshop or as a fixer mason on site. They must be able to take rough blocks of stone and transform them into the required shapes for specific projects. This is done using a variety of tools, such as saws, hammers and chisels. They must be able to read the grain patterns of the stone and determine where it will split or cleave, as well as how to cut the stones to the right size for their intended use.

A carver mason is in demand for their artistic skills and can create a wide range of patterns and designs. They can create everything from animal statues to human figures and other sculptures. They are known for their ability to carve detailed shapes with precision and accuracy.

A monumental mason works on a larger scale and builds more intricate structures, such as bridges or towers. They can also work on large-scale stone carving, such as the façades of cathedrals. The job is a highly specialised field and requires a high level of skill. Those who want to pursue this career must complete a stonemason apprenticeship, which usually takes 42 months and is available as a school-based apprenticeship.

Tools

A stone mason uses a wide variety of tools for his craft. These include a number of different types of trowels that are used for spreading mortar, laying bricks, and more. Other important masonry tools include a hammer, chisels, and brushes. Some stonemasons also use a spirit level and a plump bob to measure the verticality of walls, while others use a mason’s square or a level to set out right angles.

A scabbling hammer, sometimes known as a scappling hammer, is a huge tool with a substantial iron head and a lengthy wooden handle. It is used to remove minor protrusion and uneven bushings from the face of stones, ensuring that they are perfectly straight. A stone mason must be able to identify and correct any unnatural angles in order to ensure that his work is high quality.

Another essential masonry tool is a pitching tool, which is used to rough up the surface of stones. It is a two-sided hand tool that has a flat face and a tapered end. The rounded end is often used to hammer nails, while the flat face allows it to deliver a blow similar to that of a metal hammer or mallet. The pitching tool can also be utilised to shave away any excess stone.

Other useful masonry tools include a tuck pointer, a pointing trowel, and a margin trowel. These are used for more detailed masonry work, including filling in the seams of a wall. In addition, a mason may also use a walling hammer, which is used to deliver a more powerful blow than the tuck pointer or pointing trowel.

Some masons also use power saws to cut through hard materials like bricks. This is a fast, efficient way to build structures that would otherwise take a long time to complete by hand. Masons must be skilled at operating these machines in order to avoid damaging the surrounding surfaces.

A stone mason also has a range of brushes that are used to clean up debris and excess mortar from his work area. These can be made from a variety of materials, such as metal, fiberglass, and even wood. A good mason will always have a few of these on hand at all times.

Training

If you have a passion for working with stone and would like to become a mason, there are a number of routes into the profession. These include college courses, apprenticeships and on the job training. While many of these options require some level of qualifications, employers are usually more interested in whether you are enthusiastic and willing to learn the skills of the trade.

A brick and stone mason focuses on building walls, partitions, arches, patios, paved surfaces, fireplaces and chimneys using brick, concrete blocks, natural or manufactured stones and other masonry units. They can also repair existing structures such as walls, gates and fences. Masons are often trained to use heavy machinery to cut and shape the stone as well as to lay it in place.

Stone masons who work on building sites may need to be certified to operate cranes and hoists. They may also need to be competent at reading and interpreting construction blueprints. They need to be physically strong and able to handle heavy stone blocks and other materials. They must be able to work outdoors in noisy areas and for extended periods of time.

Apprenticeships are an ideal route into the profession, especially for those with no previous experience in the construction industry. These generally involve a year of full-time study at a local college alongside work on site. After completion, you can gain a range of qualifications including a Construction Skills Certification Scheme card.

Those interested in carving patterns into stone or creating other forms of decorative art should consider carver mason training. These are specialised masons who are often commissioned for specific projects, such as carving headstones for graveyards or monuments for churches and cathedrals.

In addition to their specialised skills, stonemasons should be skilled in measuring and cutting materials with precision. They should also be able to read and interpret construction blueprints as well as the ability to problem-solve. If you are serious about becoming a stonemason, try to find a local mason who is willing to train you. Most stonemasons are more than happy to share their expertise and help you achieve your goals.

Salary

The salary of a stone mason can vary depending on the level of expertise and experience. Those who have completed a four year apprenticeship can expect to earn professional wages. This is because they are able to work on their own and have proven skills and knowledge of the trade. In addition, they can complete more complicated projects and have the opportunity to move into supervisory roles.

The job of a stone mason is very physically demanding and can require a lot of strength, endurance and manual dexterity. They also need to be very familiar with the different types of stones that they use and how they behave. Many stone masons also need to know how to read and interpret blueprints in order to correctly proportion their materials and ensure they have enough for the project.

Some stone masons specialise in particular areas of masonry, such as kitchen benchtops or bathroom vanities. These masons may be based in workshops and cut the stone according to specifications provided by builders or other designers. They can also install these construction elements on-site, following the instructions in the blueprints.

Other stone masons focus on building structures and monuments, including bridges, churches and other historic buildings. They often work outdoors and must deal with inclement weather conditions, which can make the job more difficult. These stonemasons may need to be able to operate heavy equipment and may need to work at heights.

There are also a number of stone masons who focus on memorial work and can be found in funeral parlours and crematoriums, where they carve intricate inscriptions into headstones and other graveyard fixtures. They may also be required to carry out heritage restoration or corrective masonry work.

The work of a stone mason requires a high degree of precision and attention to detail, in order to ensure that the finished product is both functional and aesthetically pleasing. They also need to be able to work well with other tradespeople, such as bricklayers and plumbers, in order to complete the tasks set out in the blueprints. In addition, they should be able to communicate effectively with clients in order to understand their requirements and ensure the final product is satisfactory.

Roofing – The First Line of Defense Against the Elements

The roof encloses the interior space of a house, protects it from weather elements and adds to its appearance. A well maintained roof also increases the value of a home.

A roof can be flat or have a slope. It may have a gable shape with two sides that meet at the ridge or a hip roof with three sides. Contact Roofing Corpus Christi TX now!

When you’re looking to have your roof replaced, it’s important to choose a sturdy material that will add value to your home. A good roof will also protect your house from rain, snow and other elements. There are many different types of roofing materials to consider, each with its own strengths and weaknesses. Some are better suited for certain climates than others, while other roofing materials can enhance the aesthetic of your house.

One of the most popular and attractive roofing materials is wood. It looks lovely on classic and historic-style homes, such as Cape Cod cottages or Craftsman houses. There are two basic types of wood roofs, shingles and shakes. Shingles are thin slabs that are produced by precise sawing, while shakes are thick wedges that have a rougher texture. Both shingles and shakes can be stained to match the color of your house. Wood is not as long-lasting as other roofing materials, especially in damp climates, but it can last a lifetime if well maintained.

Metal roofing is a durable option that has been known to last up to 50 years. It’s available in several styles, including standing seam and shingle look-alikes. One of the newest roofing materials is composite shingles, which are made from recycled plastic and rubber. These are a great alternative to wood or slate roofs, as they have the same look but come in at a more affordable price point.

Concrete tiles are another durable roofing material that is suitable for a range of climates. They’re fire-resistant, moisture-proof and can resist wind damage. They’re available in a wide range of colors and are less expensive than clay tiles.

For flat or low-pitch roofs, a membrane roofing system is an excellent choice. This type of roof is typically made with EPDM, a synthetic rubber sheeting. It’s affordable, easy to install and repair, and offers excellent durability.

Rolled roofing, which is a single piece of black or tan canvas that’s nailed to the roof, is another roofing option. It’s affordable, but doesn’t add much to the resale value of your house.

Roofing Installation

The roof is one of the most important aspects of a home, protecting it from rain, snow, sunlight, wind, and extremes of temperature. It’s also a major investment. While any part of your house can be damaged by the elements, it’s typically your roof that takes the brunt of the abuse. That’s why it’s so important to choose the right material and have it installed properly.

Before any roofing work can begin, the crew will need to get set up. This involves finding the access point, getting their tools ready, and doing whatever else is necessary to prepare the property. The crew will also cover your yard, pool or deck, and move any items that may be in the way of the workers. Tarps will then be attached to the roof and wooden boards will cover any areas that may be harmed by debris falling from the roof during the reroofing process.

Once the protective coverings are in place, the roofing crew will begin working on the most visible element of your new roof–the shingles. The shingles will be laid in layers, staggered, and nailed in. This is an artful, time-consuming process that requires a certain amount of skill. A top-notch roofer will take care to do a beautiful job that keeps the weather elements out and your family comfortable.

Additional protection for your roof can be added with flashing, a metal material that’s placed around chimneys, windows, and any other joints. Specialty shingle caps are also available for the ridge of your roof to provide both a finished look and extra moisture and wind resistance. Finally, soffit and gable vents are added to remove moisture and heat from the attic, regulate the temperature in your home, and reduce energy costs.

Roofing Repair

While any part of the house takes a beating from the elements, the roof is typically where the heaviest assaults are experienced. Rain, hail, sleet, snow, bitter cold, hot sun, and the occasional flying object or fallen tree can all take their toll.

Repairing a roof isn’t as simple as just replacing the damaged shingles, though. Depending on the roofing materials and extent of the damage, it could take several days to complete a full reroofing job.

The first step is assessing the damaged area, which will usually be apparent from within the home. Look for stained ceilings, deteriorating insulation, or other signs of leaks. You may also notice that some areas of the roof are warmer or cooler than others, which can be a sign of roof damage.

Next, remove any debris that’s blocking access to the damaged areas of the roof. If the flashing (thin metal that’s often hand-bent around parts of the roof, like pipes) is damaged, try to remove any nails and sealant from it, then re-bend and re-seal it.

Roofing Maintenance

Your roof is the first line of defense between your living environment and outside elements. Even small problems can escalate quickly, becoming expensive to repair. Regular maintenance by a qualified roofing professional can prevent these issues and help you avoid costly repairs down the road. During a maintenance visit, the roofing professional can inspect the entire roof and document conditions with a checklist. The checklist will be tailored to each individual facility. It will include pictures, roof dimensions and applied systems. A detailed inspection of the flashings (where a majority of leaks originate) should also be done. Lastly, the field should be inspected for surface wear, lap integrity and overall degradation.

The gutters should be inspected and downspouts cleared of debris to ensure proper flow of water. Trimming large tree limbs that hang over the roof can be a good way to protect it from damage during heavy storms and natural disasters.

They Have Financing Options

Roofers help keep buildings protected by installing, repairing, or replacing their roofs. They work with a variety of materials, including shingles and bitumen. This in-demand career is perfect for people who enjoy climbing to high heights, working with their hands, and solving problems. Typically, roofers complete a high school diploma and pursue an apprenticeship or trade school to learn their craft. Some even have specialized certifications for specific types of roofing.

Many roofers offer financing for their services. Large, nationwide companies often have their own in-house financing providers. This helps make the entire process easier for homeowners, as they can get approved and receive funds in as little as 24 hours. These companies also tend to have lower interest rates than credit cards, and you won’t be penalized for paying back your loan early.

Besides offering their own financing, most roofers partner with third-party lenders to provide loans for roofing projects. Some lenders, like Upgrade, specialize in home improvement financing, so they know what it takes to finance a roof project. Their online application is easy, and they don’t charge a prepayment penalty for paying your loan off early.

If you’re not comfortable with a personal loan, you may be interested in a home equity line of credit (HELOC). Similar to a credit card, you can borrow up to a certain limit, and the interest you pay is tax-deductible. However, HELOCs require you to pledge your home as collateral, so it’s best used for long-term or surprise expenses.

Another option is to use a credit card with 0% interest for six or 12 months. This can be a good way to fund your roof, but you should be aware of the APR after that promotional period ends. Additionally, most credit cards will charge a transaction fee when you make a purchase, which can add up over time.

What is Grease Trap?

Grease Trap Perth reduce the amount of fats, oils and greases (FOG) that enter sewer systems. They are located outside and protected by manhole covers.

FOG blockages cause costly plumbing problems and unpleasant odours. Prioritising grease trap maintenance eliminates blockages, reduces operating disruptions and enables compliance with regulations. There are several types of grease traps available: passive, hydromechanical and automatic.

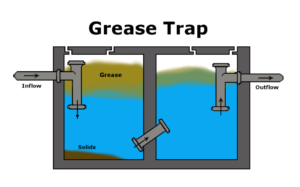

Grease traps are interceptors that separate FOG from wastewater before it enters sewage systems. This prevents clogged drain pipes, reduces the risk of blockages in commercial kitchens and food-related businesses and eliminates unpleasant odours. Regularly cleaning and pumping out grease traps also reduces the likelihood of costly plumbing problems and hefty fines from regulatory authorities.

Generally, there are 3 main types of grease trap; passive hydromechanical (manual), automatic and gravity. Each type has its own unique design and application but they all work by slowing the flow of wastewater from sinks and dishwashers, separating out FOG which then floats to the top of the trap. The filtered wastewater then exits through the rest of the drain system.

Passive hydromechanical systems, such as the Aqua Mundus AGT-40, 80 or 120, are a cost-effective solution for below-sink installation in restaurants and other commercial food services. They feature a large stainless steel tank that sits underneath sinks and features a hinged lid. Before opening the lid, it is important to allow the grease to cool down – the warmer liquid tends to float more and can potentially cause a mess if spilled. Once the lid is open, users need to clean the grease trap using a variety of tools such as rubber gloves, a mask or nose plug for defence against odours, a crowbar, dish soap and a shop vacuum.

Once the trap is cleaned it is important to note that there is a 25% limit on the total depth of grease and sediment in the trap. It is recommended that the grease and sediment layer does not exceed this limit to ensure the trap continues to function effectively. For this reason, it is advisable to regularly monitor the levels of FOG in the trap via real-time monitoring systems such as those offered by Aqua Mundus.

Alternatively, automatic systems, such as the AGRU (automatic grease removal unit) offer a more efficient and cost-effective alternative to passive traps. They use similar principles to a passive trap but re-heat and skim the FOG on a programmed schedule, moving it into a separate grease collection bin for easy recycling and disposal. They are available in a range of sizes to suit different requirements and have the added benefit of being more eco-friendly as the removed grease can be recycled into biodiesel.

Finally, a gravity system is a large in-ground tank made from concrete, fibreglass or steel and works in a similar way to a passive system but with a much larger capacity, making them ideal for high-flow applications. These require a more comprehensive maintenance regime with the FOG being pumped out on a scheduled basis, usually by a specialist grease management service company. The advantage of this is that the trapped grease can be disposed of and sold to generate income for the business.

Automatic

Grease traps are essential for preventing FOG from entering the sewage system where it can cool and solidify to block sewer lines and cause costly blockages. Effective grease management strategies include investing in appropriate equipment based on business needs, training staff to minimise FOG contributions and partnering with professional services for specialised cleaning and maintenance. Regular inspections are also vital to identify issues in the early stages and ensure timely cleaning or replacement.

There are 3 main types of grease trap; passive hydromechanical (manual), automatic and gravity. Manual traps are often used in smaller establishments as they offer a lower purchase cost and do not require electricity to operate. They can still be susceptible to odour problems however and require frequent cleaning. In comparison, automatic traps have a high initial investment cost and are usually dependent on electricity to operate. However, they are more efficient at trapping larger food particles and reduce the frequency of maintenance compared to manual models, only requiring around 10 minutes of daily operation and no electricity supply.

Both manual and automatic grease traps can have a positive impact on the environment by preventing FOG from entering the sewerage system where it can cause blockages. However, what differs between the two systems is how the pumped out waste is disposed of. With manual traps, the grease management service company who pump out the trap will typically recycle the fats, oils and grease into biodiesel or dispose of it in a more environmentally conscious manner.

On the other hand, with an automatic grease removal unit (AGRU) the removed grease can be sold as a product helping to reduce waste disposal costs. This gives the AGRU the edge over the manual trap in terms of being eco-friendly.

As the name suggests, the AGRU is a ‘grease removal’ unit which removes the FOG from the water before it enters the sewerage system. As the wastewater passes through the interceptor, the solid waste will settle in the bottom and the lighter fats, oils and grease will float to the top. This natural separation process allows relatively grease-free wastewater to pass into the sewerage system. However, it is important to note that the AGRU should be regularly emptied of the solid waste and floating grease to prevent excessive build up. As a guide, the sediment and floating grease depth should not exceed 25% of total liquid depth. If this is not done regularly the performance of the unit will diminish. For this reason, the AGRU is best suited for businesses with plenty of vertical space available for the container to be lifted out. This can be an issue with certain kitchen layouts and may not be suitable for all sites. The AGRU is also more expensive than the manual trap to purchase.

Gravity

A gravity grease trap is a receptacle into which wastewater containing FOG flows before entering a sanitary sewer system. These receptacles are designed to intercept or “trap” the FOG while allowing clear water to escape. While it is difficult to stop all kitchen wastewater from entering drains and a commercial sewer system, a grease trap can help reduce the amount that does so. This helps reduce costly blockages and repairs, as well as minimizing the negative environmental impact caused by the excessive amounts of FOG that enter the sewage system.

FOG can cause significant damage to sewer lines over time if it is allowed to build up. These blockages are known as sanitary sewer overflows (SSOs) and require extensive specialized equipment, labor, and time to clear. By installing a grease trap and properly maintaining it, foodservice establishments can prevent SSOs and the associated fines, downtime, and repairs.

Passive Hydromechanical Grease Traps work by using baffles or plates that slow down the flow of wastewater in order to allow gravity to aid in separating grease from water. This type of trap is commonly made from stainless steel or epoxy coated concrete and can be placed indoors or outside, depending on the size and output of a restaurant. These types of traps are typically cheaper than automatic models and are easy to install for a commercial kitchen.

The most common method for cleaning a passive Hydromechanical trap is by manually skimming floating grease and solids from the top of the tank. Once the grease has been removed, it is then deposited into a separate watertight container for storage until the next scheduled cleaning occurrence. The volume of grease and solids removed should be recorded on a maintenance log so that the frequency of cleaning can be optimized to save money while still meeting regulatory requirements.

A passive trap that isn’t cleaned out regularly can begin to leak grease into the sanitary sewer system, which can lead to costly fines and downtime while a restaurant waits for internal plumbing to be fixed. An automatic grease removal unit can eliminate this risk by automatically removing FOG from wastewater and storing it in a contained area until the system is ready to be emptied.

It’s important to understand the different types of grease traps available so that you can choose the right one for your restaurant. With a better understanding of the difference between the three main types of grease traps, you can make an informed decision about which type is best for your business and begin taking steps toward more efficient and effective FOG management in your kitchen. Contact us for more information about choosing the right grease trap for your establishment or for assistance with any other waste management needs.