Grease Trap Perth reduce the amount of fats, oils and greases (FOG) that enter sewer systems. They are located outside and protected by manhole covers.

FOG blockages cause costly plumbing problems and unpleasant odours. Prioritising grease trap maintenance eliminates blockages, reduces operating disruptions and enables compliance with regulations. There are several types of grease traps available: passive, hydromechanical and automatic.

Grease traps are interceptors that separate FOG from wastewater before it enters sewage systems. This prevents clogged drain pipes, reduces the risk of blockages in commercial kitchens and food-related businesses and eliminates unpleasant odours. Regularly cleaning and pumping out grease traps also reduces the likelihood of costly plumbing problems and hefty fines from regulatory authorities.

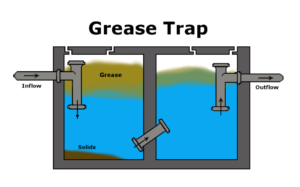

Generally, there are 3 main types of grease trap; passive hydromechanical (manual), automatic and gravity. Each type has its own unique design and application but they all work by slowing the flow of wastewater from sinks and dishwashers, separating out FOG which then floats to the top of the trap. The filtered wastewater then exits through the rest of the drain system.

Passive hydromechanical systems, such as the Aqua Mundus AGT-40, 80 or 120, are a cost-effective solution for below-sink installation in restaurants and other commercial food services. They feature a large stainless steel tank that sits underneath sinks and features a hinged lid. Before opening the lid, it is important to allow the grease to cool down – the warmer liquid tends to float more and can potentially cause a mess if spilled. Once the lid is open, users need to clean the grease trap using a variety of tools such as rubber gloves, a mask or nose plug for defence against odours, a crowbar, dish soap and a shop vacuum.

Once the trap is cleaned it is important to note that there is a 25% limit on the total depth of grease and sediment in the trap. It is recommended that the grease and sediment layer does not exceed this limit to ensure the trap continues to function effectively. For this reason, it is advisable to regularly monitor the levels of FOG in the trap via real-time monitoring systems such as those offered by Aqua Mundus.

Alternatively, automatic systems, such as the AGRU (automatic grease removal unit) offer a more efficient and cost-effective alternative to passive traps. They use similar principles to a passive trap but re-heat and skim the FOG on a programmed schedule, moving it into a separate grease collection bin for easy recycling and disposal. They are available in a range of sizes to suit different requirements and have the added benefit of being more eco-friendly as the removed grease can be recycled into biodiesel.

Finally, a gravity system is a large in-ground tank made from concrete, fibreglass or steel and works in a similar way to a passive system but with a much larger capacity, making them ideal for high-flow applications. These require a more comprehensive maintenance regime with the FOG being pumped out on a scheduled basis, usually by a specialist grease management service company. The advantage of this is that the trapped grease can be disposed of and sold to generate income for the business.

Automatic

Grease traps are essential for preventing FOG from entering the sewage system where it can cool and solidify to block sewer lines and cause costly blockages. Effective grease management strategies include investing in appropriate equipment based on business needs, training staff to minimise FOG contributions and partnering with professional services for specialised cleaning and maintenance. Regular inspections are also vital to identify issues in the early stages and ensure timely cleaning or replacement.

There are 3 main types of grease trap; passive hydromechanical (manual), automatic and gravity. Manual traps are often used in smaller establishments as they offer a lower purchase cost and do not require electricity to operate. They can still be susceptible to odour problems however and require frequent cleaning. In comparison, automatic traps have a high initial investment cost and are usually dependent on electricity to operate. However, they are more efficient at trapping larger food particles and reduce the frequency of maintenance compared to manual models, only requiring around 10 minutes of daily operation and no electricity supply.

Both manual and automatic grease traps can have a positive impact on the environment by preventing FOG from entering the sewerage system where it can cause blockages. However, what differs between the two systems is how the pumped out waste is disposed of. With manual traps, the grease management service company who pump out the trap will typically recycle the fats, oils and grease into biodiesel or dispose of it in a more environmentally conscious manner.

On the other hand, with an automatic grease removal unit (AGRU) the removed grease can be sold as a product helping to reduce waste disposal costs. This gives the AGRU the edge over the manual trap in terms of being eco-friendly.

As the name suggests, the AGRU is a ‘grease removal’ unit which removes the FOG from the water before it enters the sewerage system. As the wastewater passes through the interceptor, the solid waste will settle in the bottom and the lighter fats, oils and grease will float to the top. This natural separation process allows relatively grease-free wastewater to pass into the sewerage system. However, it is important to note that the AGRU should be regularly emptied of the solid waste and floating grease to prevent excessive build up. As a guide, the sediment and floating grease depth should not exceed 25% of total liquid depth. If this is not done regularly the performance of the unit will diminish. For this reason, the AGRU is best suited for businesses with plenty of vertical space available for the container to be lifted out. This can be an issue with certain kitchen layouts and may not be suitable for all sites. The AGRU is also more expensive than the manual trap to purchase.

Gravity

A gravity grease trap is a receptacle into which wastewater containing FOG flows before entering a sanitary sewer system. These receptacles are designed to intercept or “trap” the FOG while allowing clear water to escape. While it is difficult to stop all kitchen wastewater from entering drains and a commercial sewer system, a grease trap can help reduce the amount that does so. This helps reduce costly blockages and repairs, as well as minimizing the negative environmental impact caused by the excessive amounts of FOG that enter the sewage system.

FOG can cause significant damage to sewer lines over time if it is allowed to build up. These blockages are known as sanitary sewer overflows (SSOs) and require extensive specialized equipment, labor, and time to clear. By installing a grease trap and properly maintaining it, foodservice establishments can prevent SSOs and the associated fines, downtime, and repairs.

Passive Hydromechanical Grease Traps work by using baffles or plates that slow down the flow of wastewater in order to allow gravity to aid in separating grease from water. This type of trap is commonly made from stainless steel or epoxy coated concrete and can be placed indoors or outside, depending on the size and output of a restaurant. These types of traps are typically cheaper than automatic models and are easy to install for a commercial kitchen.

The most common method for cleaning a passive Hydromechanical trap is by manually skimming floating grease and solids from the top of the tank. Once the grease has been removed, it is then deposited into a separate watertight container for storage until the next scheduled cleaning occurrence. The volume of grease and solids removed should be recorded on a maintenance log so that the frequency of cleaning can be optimized to save money while still meeting regulatory requirements.

A passive trap that isn’t cleaned out regularly can begin to leak grease into the sanitary sewer system, which can lead to costly fines and downtime while a restaurant waits for internal plumbing to be fixed. An automatic grease removal unit can eliminate this risk by automatically removing FOG from wastewater and storing it in a contained area until the system is ready to be emptied.

It’s important to understand the different types of grease traps available so that you can choose the right one for your restaurant. With a better understanding of the difference between the three main types of grease traps, you can make an informed decision about which type is best for your business and begin taking steps toward more efficient and effective FOG management in your kitchen. Contact us for more information about choosing the right grease trap for your establishment or for assistance with any other waste management needs.